3、 Install the large transmission gear.

(1) Install the large transmission tooth on the machine screw.

(2) Install the gear key.

(3) Install the lock nut to fix the gear.

4、Install the upper cover of the connecting plate

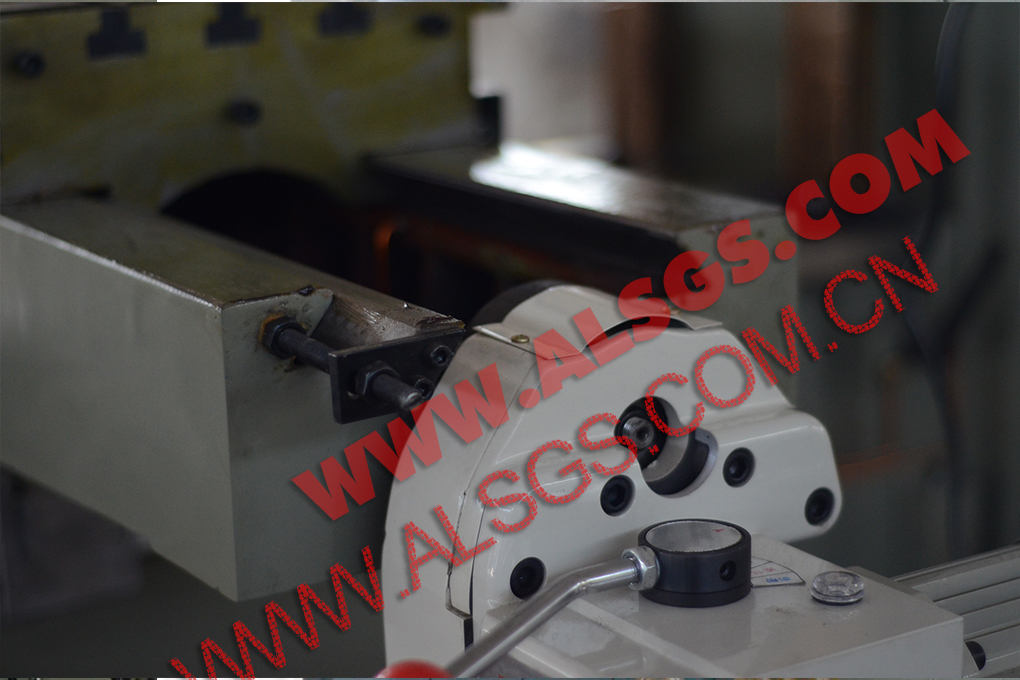

5.Take out AL-206xB mechanical power feed.

(1) On the left side of the power feed, there is a small driving tooth.

(2) When you install the tool power feed to the connecting plate, the large drive gear and the small drive gear will be engaged.

(3) The function of these two gears is to transmit the motor power to the screw rod.

(4) There is some allowance for the engagement size of the gear to facilitate the adjustment of the clearance and achieve the best engagement 1effect.

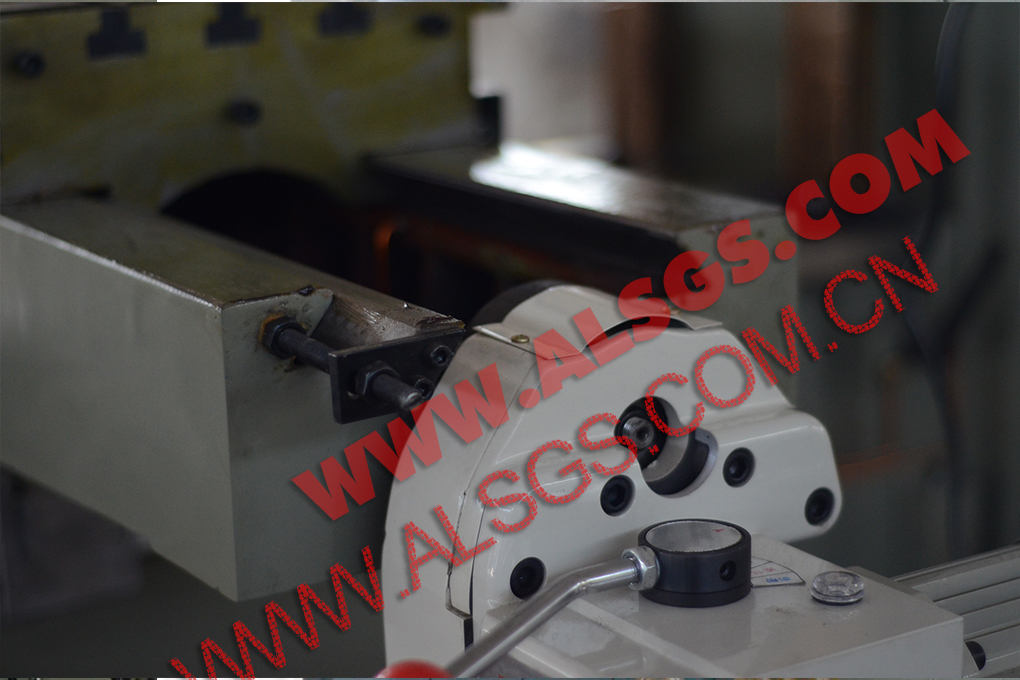

6、 Install the gear cover plate.

(1) After the cutter feeder is installed, a small amount of grease should be applied on the two transmission teeth.

(2) The function of the cover plate is to prevent the entry of iron debris, causing gear wear or stuck.

(3) There is an oil injection hole on the top of the tool feeder, and 100-200ml gear lubricating oil should be injected before use.

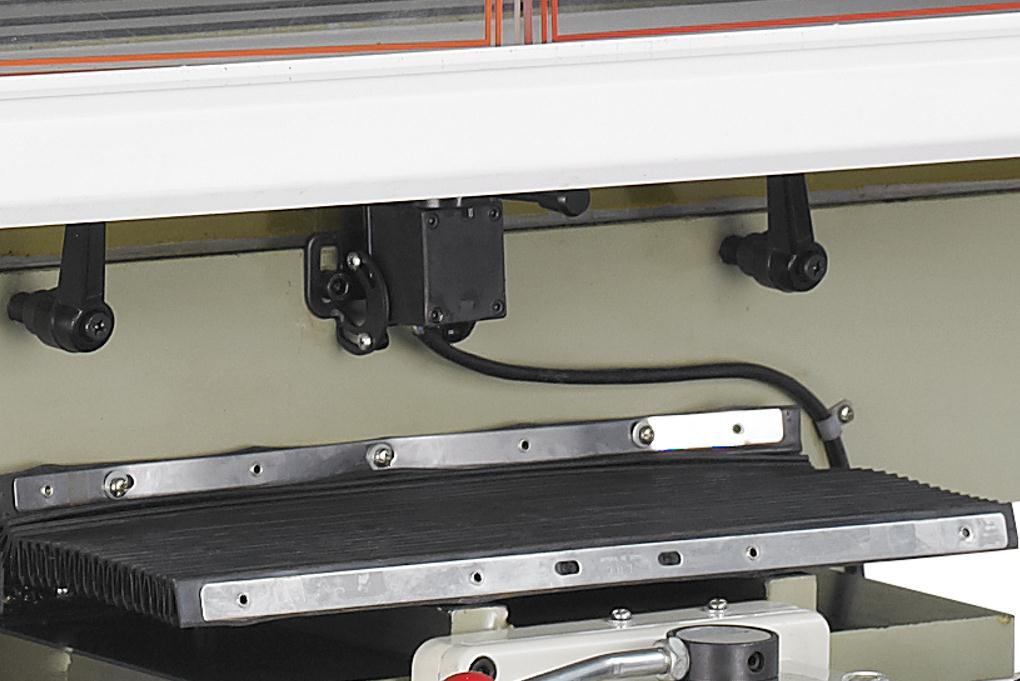

7、Install reversing limit switch.

(1) The reversing limit switch is installed on the front of the machine tool workbench.

(2) Most of the machine tools have reserved screw holes in the middle of the saddle. We only need to fix them.

(3) Install the limit bumpers.

(4) Test whether the reversing switch works normally and whether the bump block can trigger with the switch effectively.

(5) For three-phase motors, the phase sequence should be adjusted to make the moving direction consistent with the switch indication, otherwise the limit will be invalid.

8、installation is complete.

ALSGS NEWS

ALSGS NEWS